Nylon Ripstop: Everything You Need to Know

9th December, 2022

Nylon ripstop is a material commonly used in outdoor gear and apparel. It is available in light, medium, and heavy weights.

It is strong, resilient, and waterproof, making it suitable for products that require a lot of wear and tear but before we dive in, what exactly is Nylon Ripstop? How is it made? What are its best applications?

What is Nylon Ripstop?

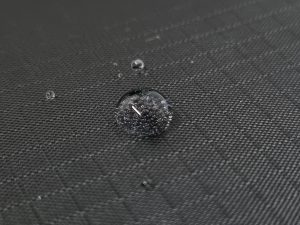

It is a fabric that is extremely resistant to rips and tears. It is a lightweight, water-repellent nylon fabric woven in a tight, reinforcing pattern commonly used in outdoor gear and apparel.

Let’s go back in time…

Nylon is a synthetic fibre that was first invented in 1935 for creating toothbrush bristles and later used to make women’s pantyhose, which became a commercial success and sparked widespread public attention.

To understand how ripstop nylon is made, it is necessary to first learn about it’s history.

Nylon has been a useful human material throughout history due to its durability, however, the demand for nylon surged during World War II, when most of the nylon manufactured in the United States was utilized as an alternative for manufacturing parachutes and other military gear.

During this period, the nylon ripstop was invented, and after the war, the nylon ripstop became famous for various applications, including tents, sails, and flags. It is now extensively utilized in outdoor gear, clothing, home furnishings, and other goods.

How is Ripstop Nylon made?

Nylon ripstop is a woven fabric made from nylon fibers that makes it resistant to tearing and ripping.

“Ripstop” refers to a fabric that can stop or prevent ripping and tearing. It can be waterproof, water-resistant, or even fire-resistant and is used in various applications, including tents, tarps, sails, backpacks, and clothing.

The first step in making nylon ripstop is to create the yarns used to weave the fabric.

After the yarns are created, they are woven together on a loom. The warp threads are threaded through the loom’s heddles, which keep them in place. The weft threads are then passed over and under the warp threads, interlocking them together.

This process is repeated until the desired width of the fabric is obtained. After weaving, the material goes through a finishing procedure, including heat-setting, dyeing, and printing.

It is frequently coated with a resin finish, which improves its water resistance and durability.

Our Nylon Ripstop Best Sellers

What Are the Different Types of Nylon Ripstop?

Various nylon ripstop fabrics are available, each with different weight, thread count, and other characteristics.

- Lightweight nylon ripstop fabrics are commonly used to manufacture shirts, pants, and tents.

- Mid-weight nylon ripstop textiles are frequently used to manufacture sleeping bags and backpacks.

- Tarpaulins and sails made of heavy-weight nylon ripstop textiles are typically used in industrial applications.

Differences Between Nylon Ripstop and Polyester Ripstop?

There are a few differences you should consider before deciding which to use for your project:

- Nylon Ripstop absorbs more water and dries faster while polyester ripstop absorbs less water and dries slower.

- Nylon is also a more breathable fabric than polyester, making it ideal for use in warm weather. Polyester is a less breathable fabric than nylon, making it better suited for use in cooler weather.

- Nylon Ripstop is more costly, but it feels softer and more elastic. Polyester ripstop is both more durable and less expensive.

- Polyester Ripstop is more heat resistant than nylon.

- Polyester Ripstop is UV resistant and holds its colour far longer than nylon ripstop.

Our Nylon Ripstop Best Sellers

Benefits of Using Nylon Ripstop

There are many benefits to using nylon ripstop fabric, including its durability, water resistance, and breathability.

- Highly durable fabric resistant to tearing and creasing. It is also waterproof and windproof, making it an ideal choice for outdoor gear and clothing.

- It is lightweight yet strong, making it ideal for various sewing projects. It is easy to work with and sews smoothly without bunching or fraying.

Pros and Cons of Nylon Ripstop

There are many benefits and drawbacks to using nylon ripstop, and one of the most significant advantages is its durability. It can resist a lot of wear and tear, making it ideal for persons who overuse their clothing or equipment.

It is also relatively light, so even if you carry a lot of gear, you won’t feel weighed down by it.

However, there are several disadvantages to nylon ripstop. One of the most significant disadvantages is that moving around in it might be noisy.

The cloth can be difficult to stitch and is susceptible to damage from sunlight and chemicals. Furthermore, it does not breathe as well as some other materials, so you may become sweaty if you wear it in hot weather.

Our Nylon Ripstop Best Sellers

How to Care for Nylon Ripstop

Caring for your fabric is relatively easy, and with proper care, it will surely last for many years. Below are a few tips and tricks to remember:

– Wash your fabric in cool water with mild soap. Do not use bleach or any other harsh chemicals.

– Rinse your fabric thoroughly and allow it to air dry. Avoid putting the Nylon in the dryer, as this can damage the fabric.

– If you need to iron it, do so on a low setting and be sure not to overheat the material.

Conclusion

It’s no surprise that nylon ripstop has recently gained popularity. It is tear and wrinkle-resistant, durable, lightweight, ideal for a variety of projects and great for travel. It is also simple to care for, making it an excellent choice for regular use.

Visit us at UK Fabrics Online to explore more of our versatile Nylon ripstop fabrics, from casual clothes to technical gear.

All photos by UK Fabrics Online.

What ripstop material is used on oex walking trousers please.

Hi Debbie,

Thank you for your comment!

They use this ripstop: https://ukfabricsonline.com/nylon-ripstop

Their softshell trousers use something similar to this (Our is 3 ply Waterproof vs theirs only Water Resistance): https://ukfabricsonline.com/waterproof-breathable-softshell-3-ply-fleece-fabric

If you want Ultra Waterproof, Breathable, Durable and Comfortable, we would recommend our own branded fabric: https://ukfabricsonline.com/textura-wp20k-ultra-waterproof-breathable-outdoor-fabric

For context, our branded fabric, Textura™ WP20K Ultra, is is suitable for all weather conditions, extreme sports included, with a hydrostatic head rating of 20,000mm+. Ripstop is 1000mm+ and our softshell is 10.000mm+.

If you are still unsure, send us an email to orders@ukfabricsonline and one our expert in waterproof fabrics will help choosing the right fabric for your project.

Best regards,

UK Fabrics Online.

Our motorcycle rain gear is ripstop. Having been stored away for some time, now used in a humid environment, it is growing mold. Please advise best way to 1. Clean it thoroughly, 2. Store away again in this climate.

Thank you VERY much!

Molly from Canada, in Portugal

Hi Molly,

Thanks for the comment!

– Brush off any visible mold or mildew using a soft brush.

– Mix a solution of equal parts water and white vinegar or bicarb soda.

– Gently scrub the affected areas with the solution using a sponge.

– Rinse thoroughly with clean water.

– Air dry it completely.

– Ensure it is completely dry before storing.

The three main things when storing are avoid direct sunlight, make sure it is cool and try to use breathable storage bags that allow air circulation.

These are general cleaning guidelines based on feedback only and individual results may vary depending on the condition of the fabric and the cleaning method used.

If you have any more questions, please don’t hesitate to contact us straight away.

Best regards,

UK Fabrics Online.